If you’ve ever printed with a FDM style 3D printer such as MakerBox, I’m sure you know that the build platform has to be pretty flat and level for you to have a successful build.

The first layer is critical. If you do not get the first layer right, things go bad. I wrote about this a while ago here: https://blog.gahooa.com/2013/08/10/makerbot-replicator-2-tip-first-layer-just-right/

I was having continuous problems with the first layer being too close in the center and too far on the edges of the build plate. It was like a lose/lose on a bigger build. On smaller parts I could calibrate it so it would work fine, but larger parts inevitably ended up being wrong either in the middle or the sides.

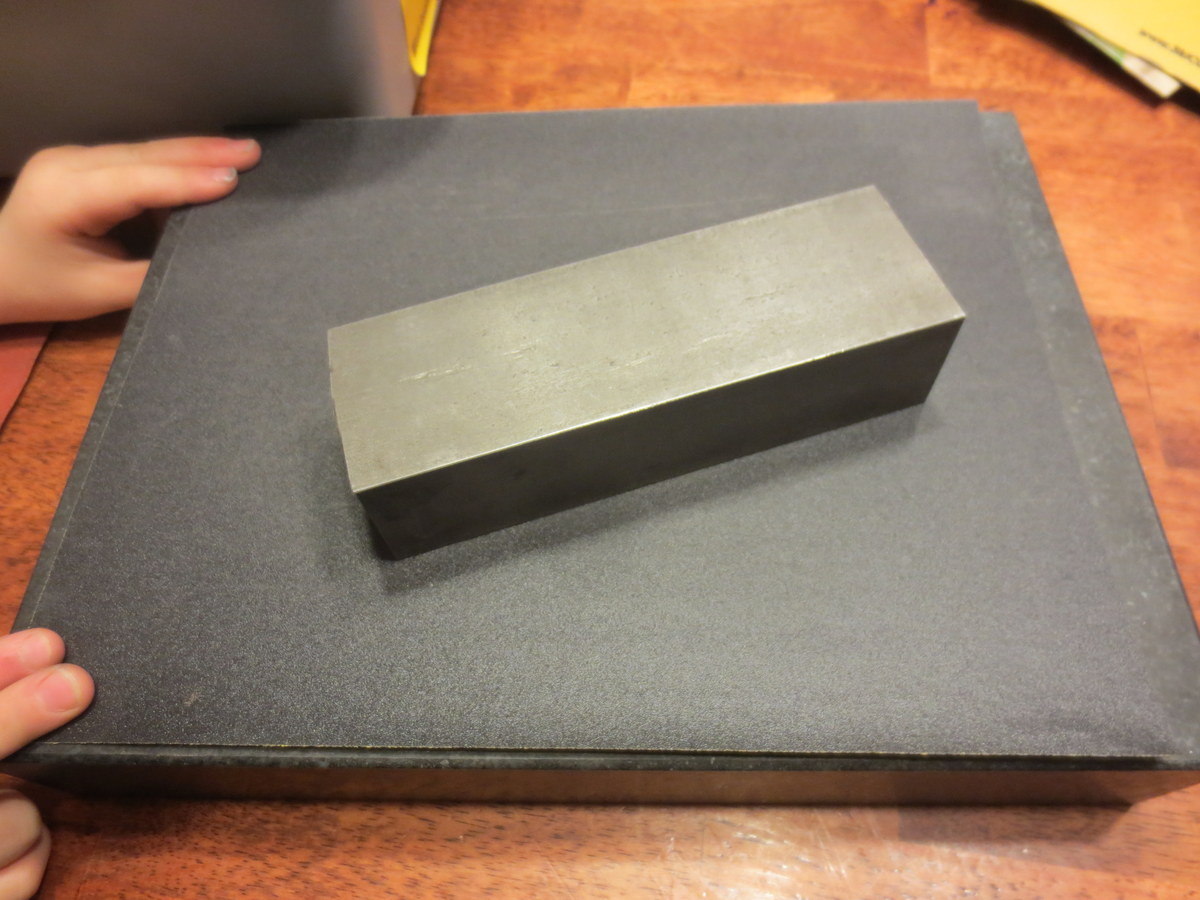

Enough is enough. A Mitutoyo Digital Indicator, a Starrett Indicator Holder, a Precision Granite Surface Plate, and time to figure this out.

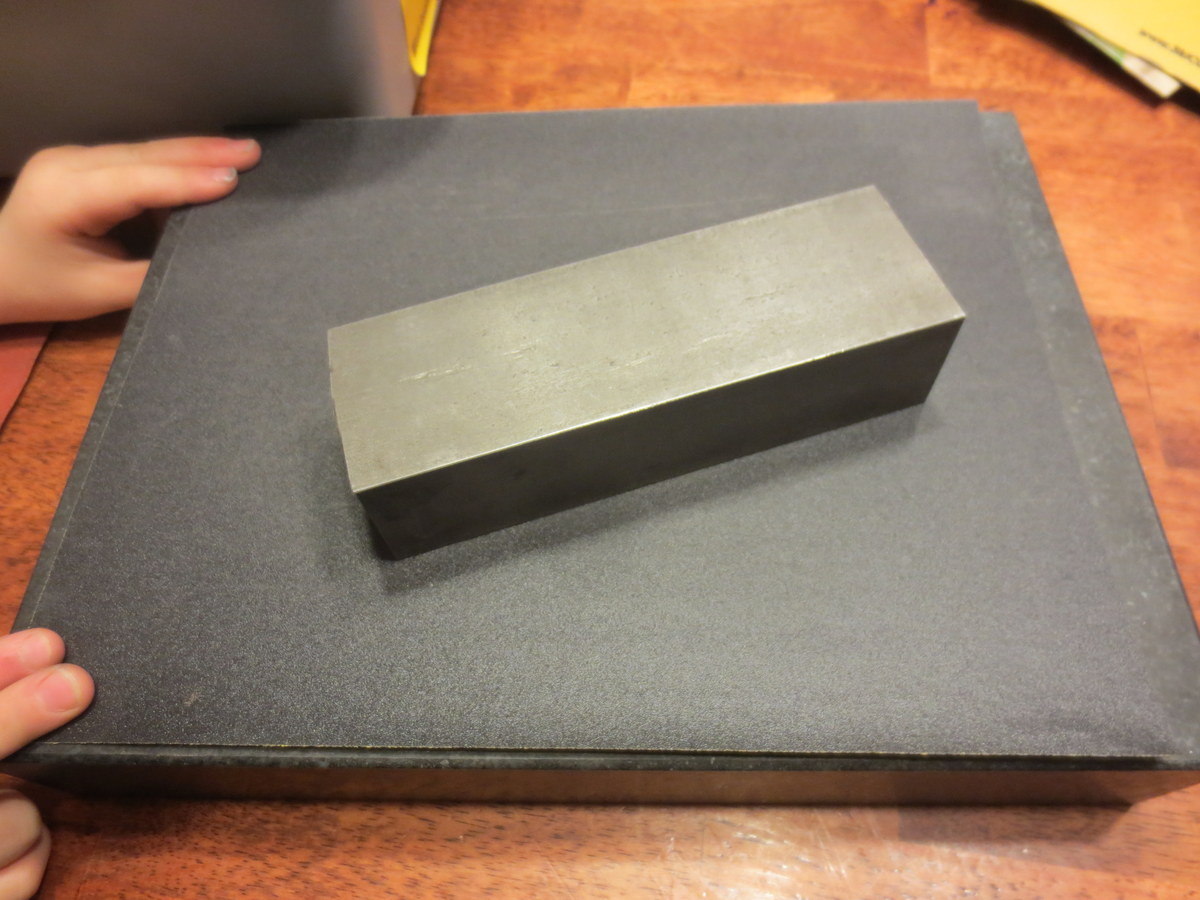

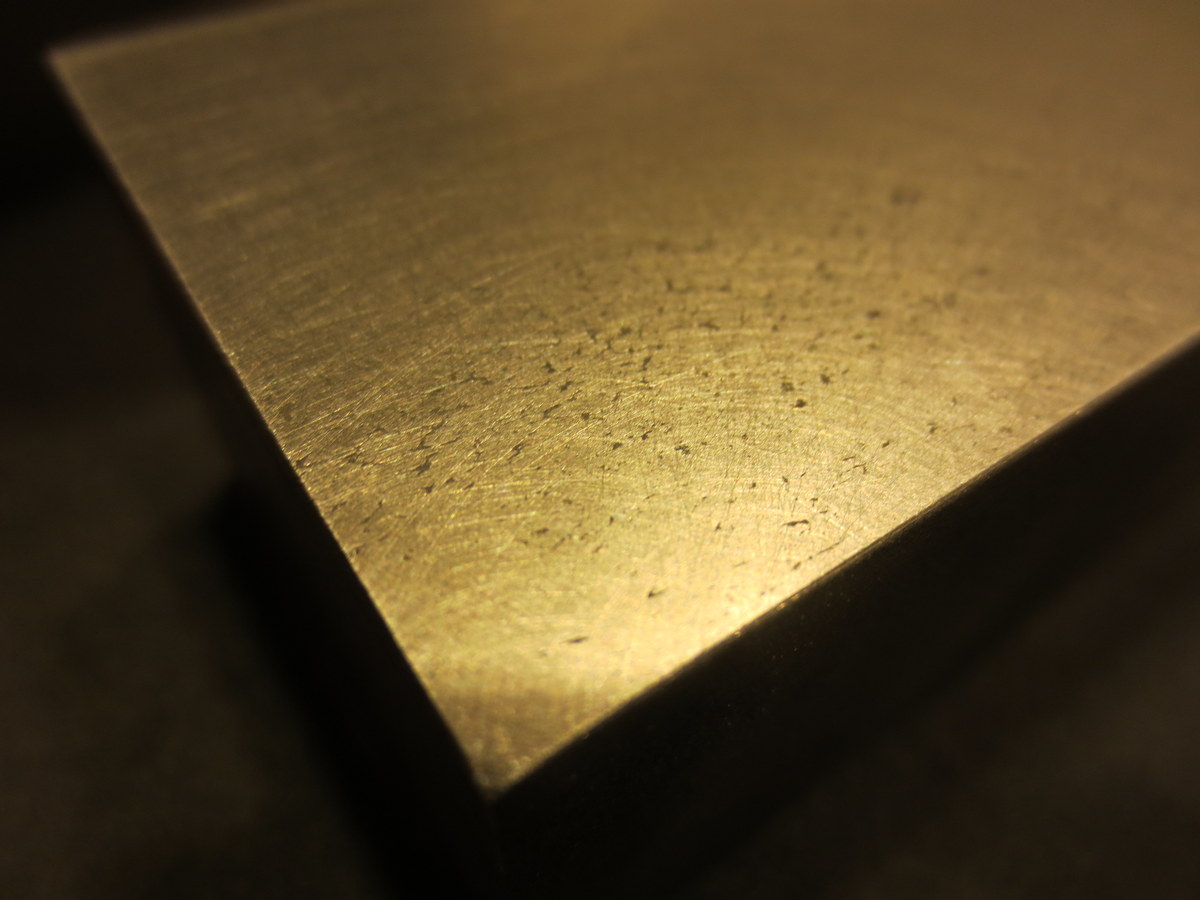

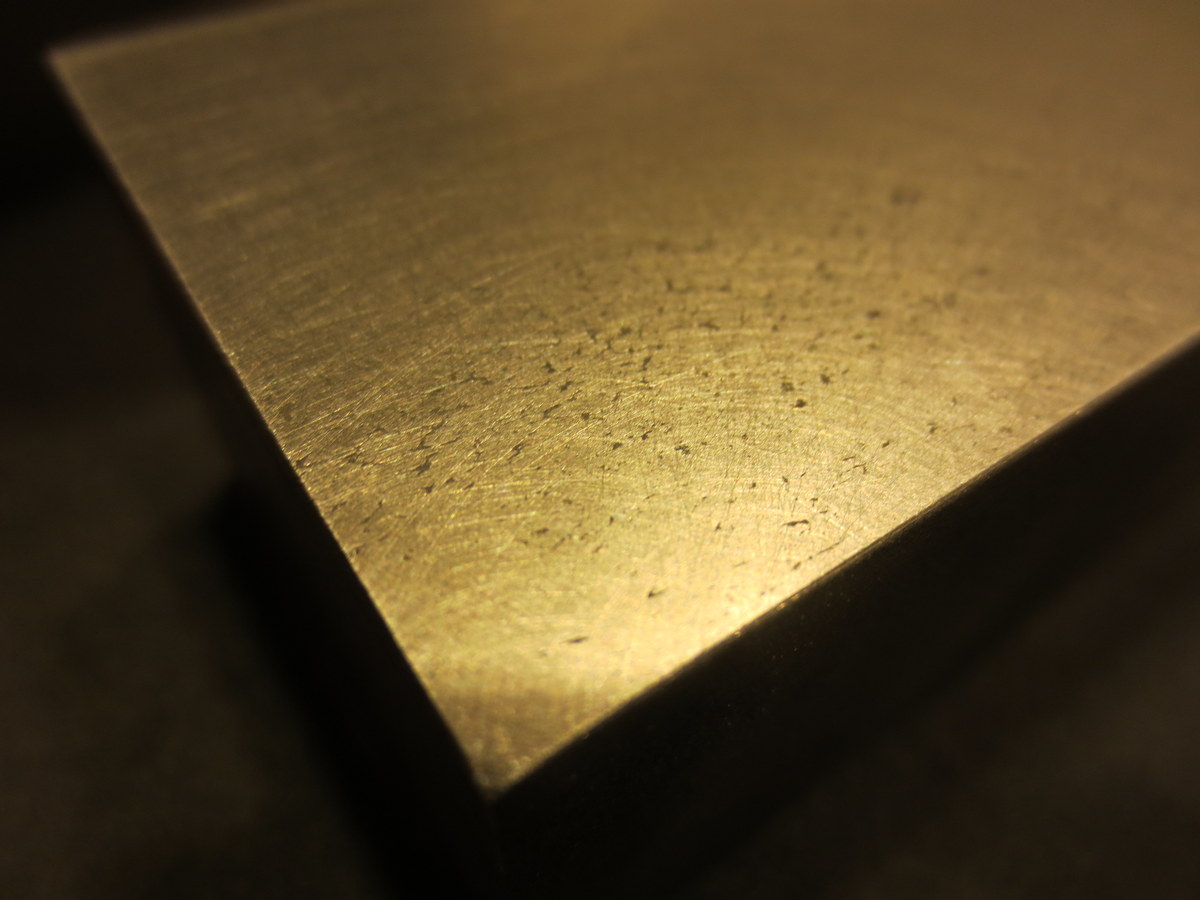

While there are more conventional ways to do this, I did not have the right equipment. So I took a steel bar and flattened it on a granite surface plate with sandpaper (60 – 2000 grit). It ended up with a very flat mirror finish on the bottom.

I did not take the time to get all of the pits out of the steel, but here is a closeup of the steel after sanding:

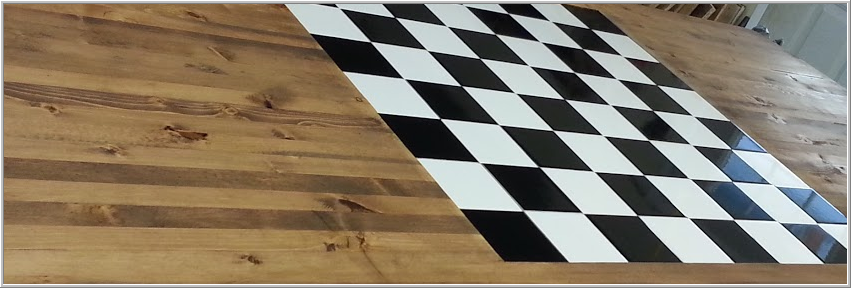

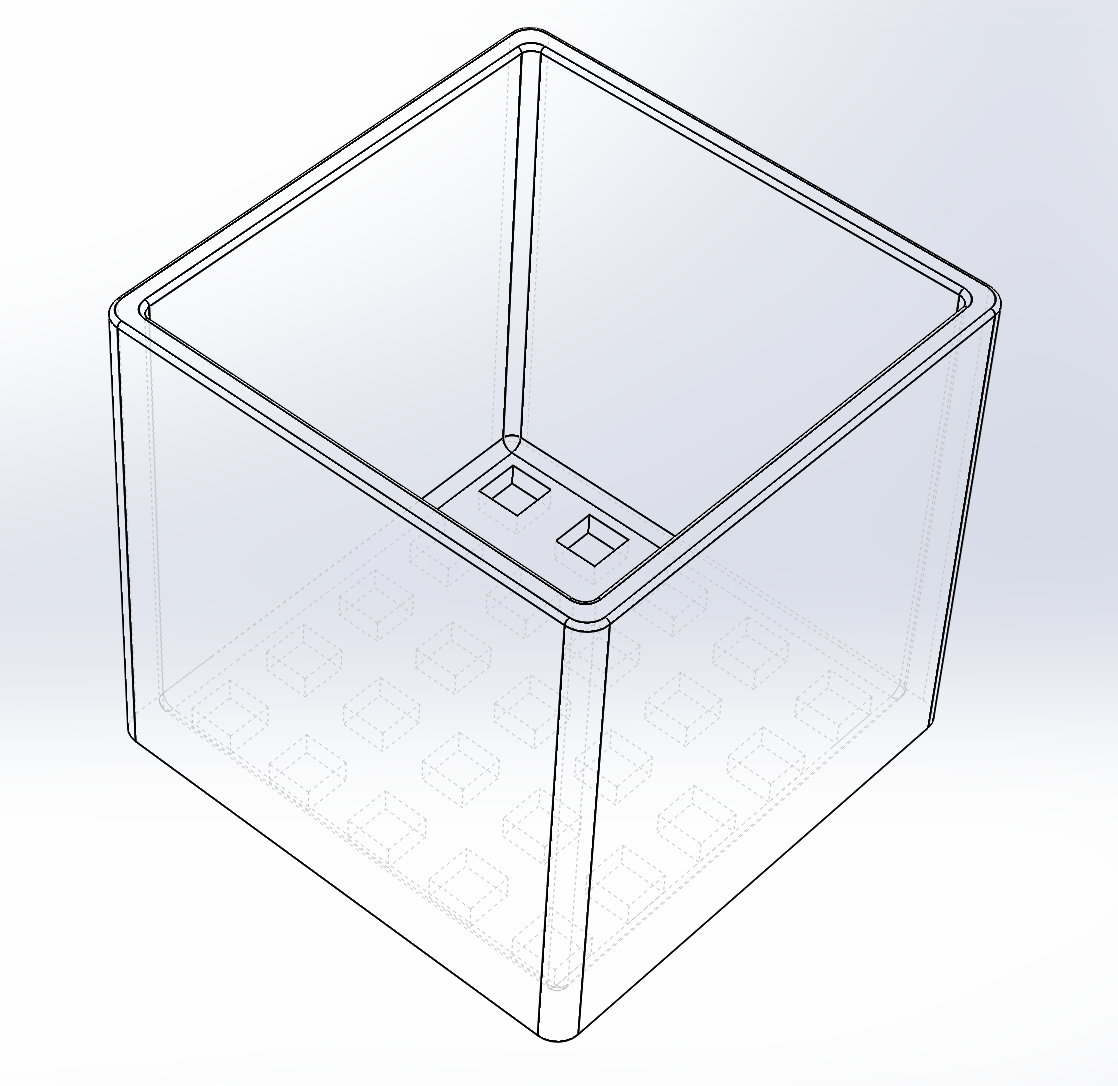

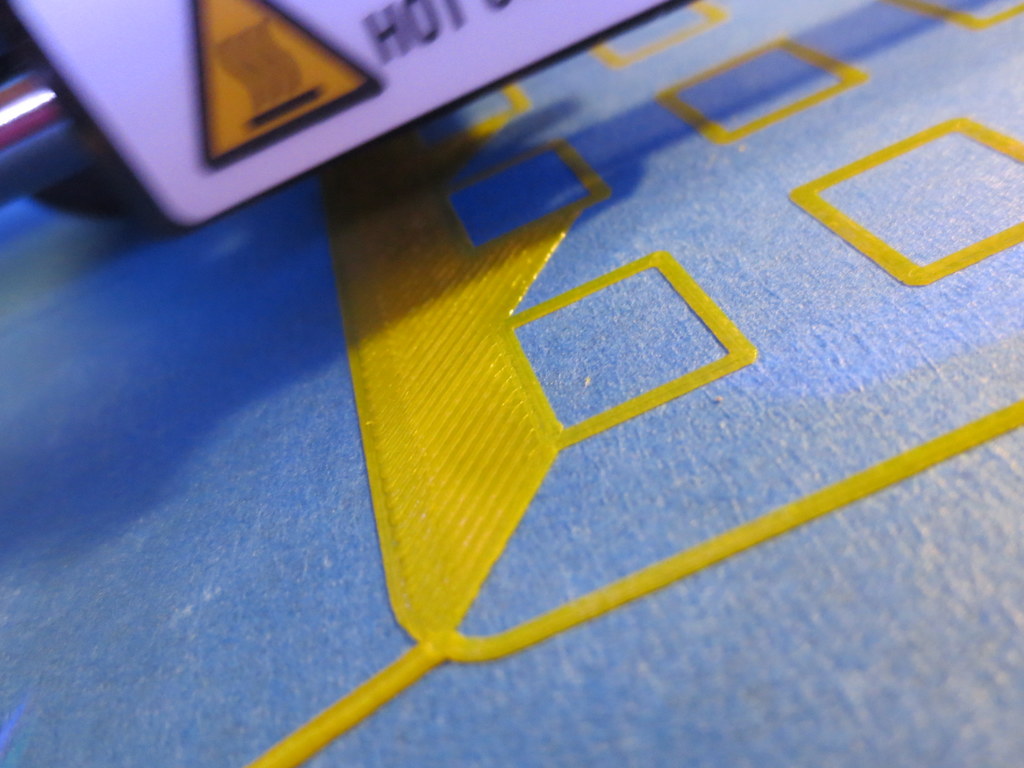

Next I measured out a grid on the Acrylic Build Plate.

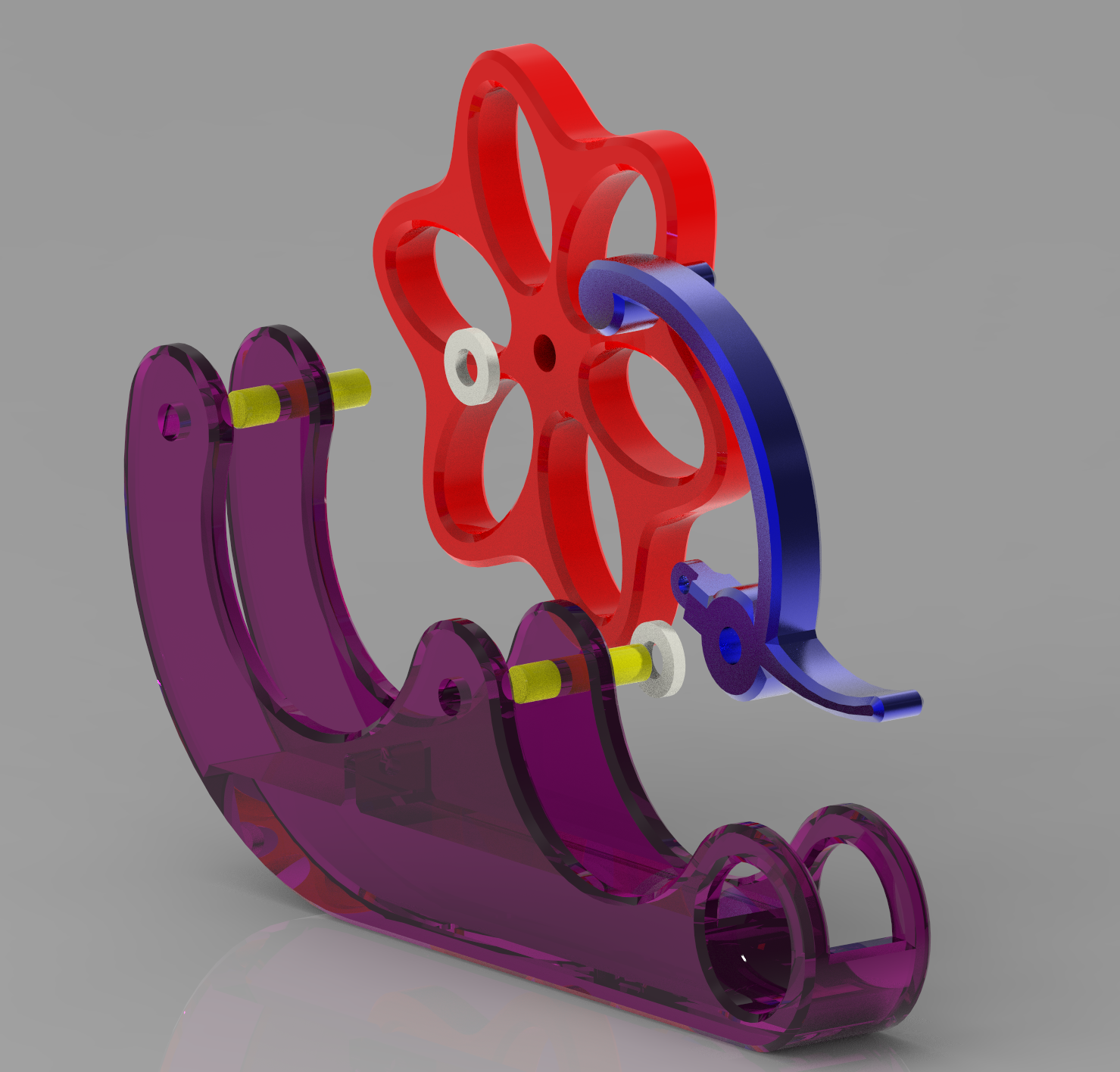

Using the digital indicator mounted to the steel block, I was able to take height measurements on the grid.

Here is a wider view, including my high tech data collection process.

Note: I did this with both the Acrylic OEM plate and a Glass Aftermarket Plate.

Once I had the data points collected, I made an exaggerated model in Sketchup, and plotted the points in 3D.

The one that is wildly out of specs is the Acrylic, and the one that has a slight dip in the middle is the Glass.

Both plates were fairly warped in my opinion. The glass was a lot more workable. I eventually bought a CNC machined aluminum plate, but did not take the time to measure it in this same way.

I feel that the manufacturers of low end 3D printers are not paying enough attention to the stiffness of their 3-Axis mechanisms. While a FDM printer does not (should not) experience side or vertical loads during disposition, they still need to be fairly immune to vibration and even the weight of the build plate.

This was a MakerBot Replicator II – an obvious improvement over the MakerBot Replicator, and I’m sure they will continue to improve this aspect of 3D printing.