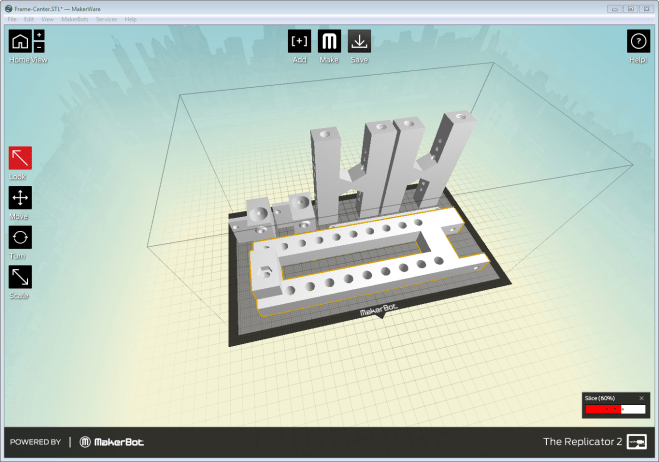

One evening of CAD. One evening of CAM. One evening of CNC. And it fit together (quite well). This is just held together with precisely located wooden dowel pins. We will add screws tomorrow.

The only missing piece is the actual guide for running the blocks through. That is separate so that it can be “dialed in” to the perfect cutting depth.