Today I learned that Creo Parametric has first class support for equations which can be turned into sketch items, and the incorporated into a model. In this example I created a sine wave.

y = sin(x*2) * 100And told Creo to extend it from x=0 to x=900. Here is a picture of editing the equation.

Once I had that curve defined, I created a sketch on the same plane, and then used the “Project” tool to project the sinewave into the current sketch. After adding sides and a bottom, I had a closed shape.

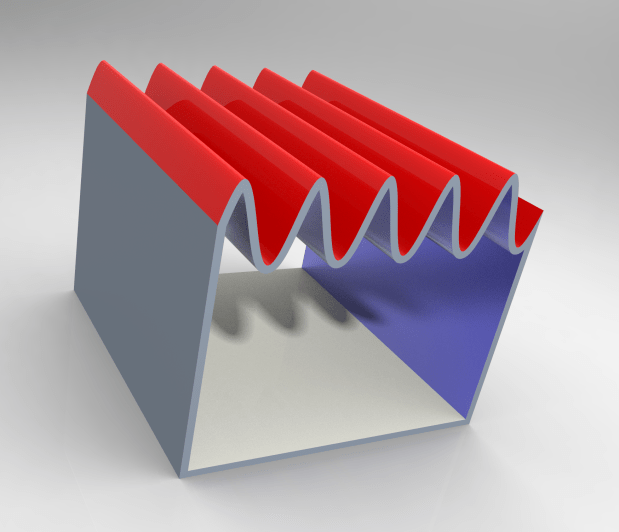

From there it was a simple matter to extrude, offset, cut, and add some colors.