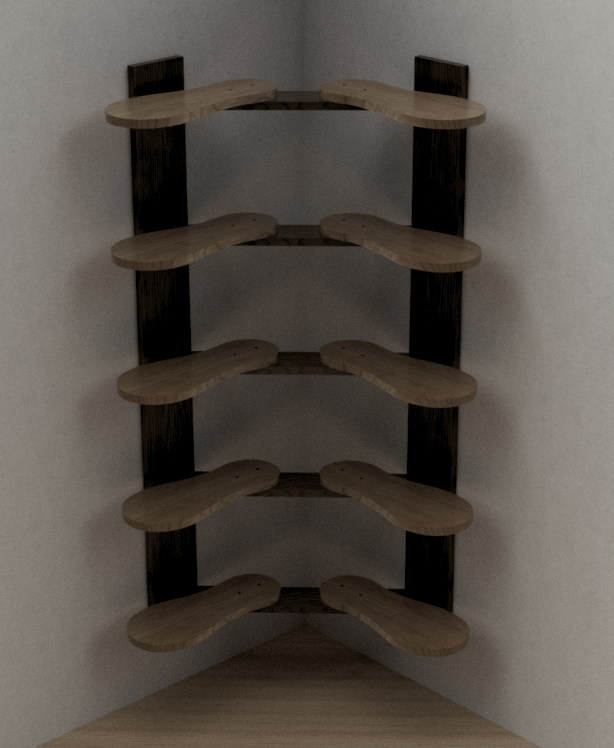

Years ago the kids and I small spice rack that we had very much outgrown. One day over the weekend I decided to organize our baking goods (which of course turned into a multi-day project of organizing the kitchen!)

With all of the kitchen counters and table covered in various containers of spices and baking goods, and it being already 9:00 PM, I took one of the kids over to the shop to put our skills to use.

Much to my dismay I found that we had a high-voltage condition on our utility power (133V), and my Phase Perfect 3-Phase converter would not start. This ruled out using the table saw, jointer, planer, and CNC router.

I thought for a couple of minutes and decided that one way or another, a spice rack was coming out of that shop without further delay. So we went into “prototype mode”. I grabbed a box of screws, a drill, an impact driver, and a bunch of OSB scraps off the rack. We used the Makita compound miter saw (fortunately not 3-phase) and a good old tape measure to whip together an (awful looking) but quite functional spice rack. We installed it, along with the iPad for recipes, and loaded it up all by 11:00 pm or so.

I am so glad it worked out this way. The concept of “prototyping” is something that is often overlooked in woodworking. But most of what we woodworkers do ends up being functional as well as gorgeous. Prototyping allows us to verify and refine the functionality prior to putting all of the effort into the real thing.

I also know from personal experience this applies to writing, software, cooking, building, inventing, sewing, and many other disciplines.