I’m a SolidWorks user and have spent considerable time with it over the past several years. Recently I heard about Onshape. It looks pretty fascinating – a fresh look at CAD – with full collaboration, versioning, and sharing.

Here is what they say about themselves:

CAD Anywhere, Anytime,

On Any Device.

Onshape is the first and only full-cloud 3D CAD system that lets everyone on a design team simultaneously work together using a web browser, phone or tablet.

—

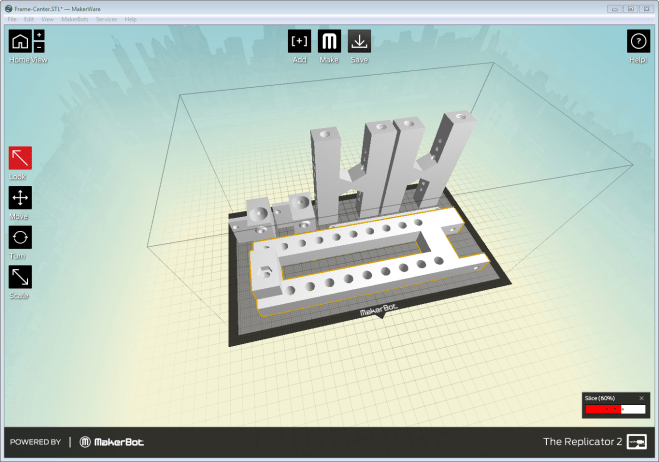

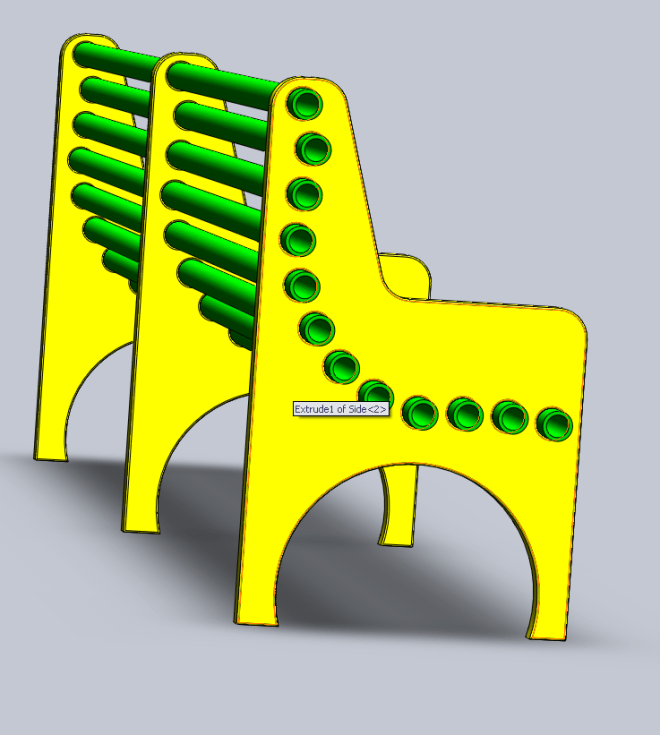

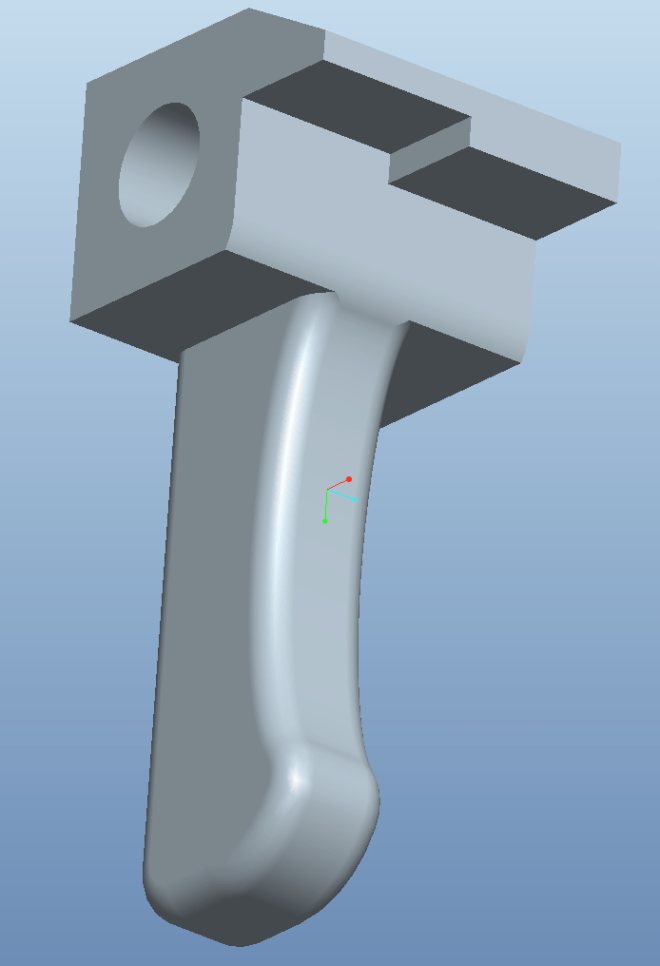

The modern web browsers are becoming a truly powerful development platform as illustrated below. The graphics are (about) as smooth as Solidworks – perhaps not quite so fancy. But being able to have your CAD anywhere is kind of exciting. They have a free plan with up to 10 drawings which would be great for schools and students and hobbyists to use.

Update From OnShape:

Jason – thank you for the blog post. We here at Onshape are very excited to make professional grade 3D CAD available to everyone for free. Just to clarify, a free user can have UNLIMITED FREE PUBLIC DOCUMENTS AND 5GB OF FREE ONLINE STORAGE. Thats a lot of whatever you’re into :)In addition – free users ALSO get 10 free private documents (not to exceed 100MB) to test Onshape against a proprietary design need.Bottom line – if you are a hobbyist or amateur, you can use Onshape for free forever.Thank you again.Philip …