This has become one of our favorites for breakfast. Perfectly cooked eggs and toast and roast beef… all on a cast iron griddle. This is the breakfast that will power your day…

Author: Jason Garber

Homemade Egg McMuffins

A touch of butter on a properly seasoned cast iron griddle… medium heat… eggs…. firm up… flip over and press down… finish up to perfect doneness.

Served with pan fried bacon and toasted english muffins.

The dogs chewed my toaster cord in half so until it is repaired, I’ve been toasting on a flat cast iron griddle. I actually like it a lot better.

Auto Loading CNC Router Jig

After years of making the same part repeatedly on the CNC router, I finally decided it was time to make the router load it’s own material.

Friction is a valid way to hold a part for routing. That is how most vices and clamps work. The key here is to calculate an amount of friction that will resist the cutting forces while at the same time keeping it low enough for the router to be able to overcome it while loading and unloading.

I’ll post more on this when we have it working. For now, here is a cool picture of the jig.

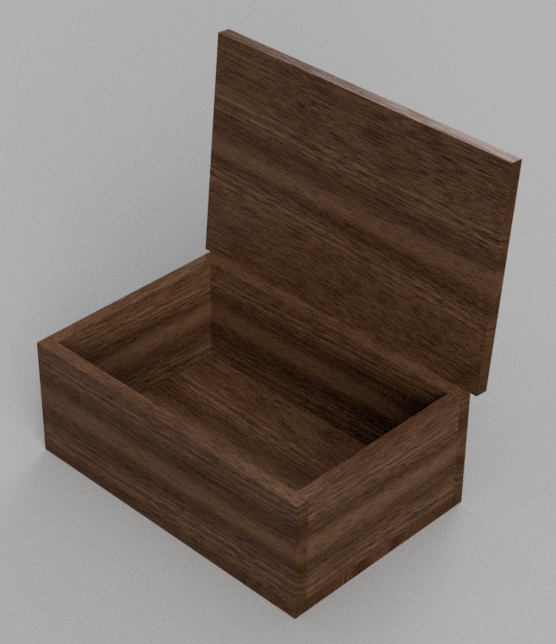

Wooden Box (Fusion 360)

Here is a box that Zechariah designed in Fusion 360 in about 20 minutes, complete with a hinged lid.

Modern CAD software is amazing.

Barrel Sander (M002) Render

All of the parts are getting into final position. Getting ready to build it!

Barrel Sander (M002) Motor Assembly

Most standard 60HZ AC motors come in approximately 3600 RPM or 1800 RPM. The barrel sander needs to spin at about 30 RPM. To achieve this, the following approximate pulley sizes will be used:

- 1800 RPM motor

- Shaft to 2″ Pulley

- Belt to 7.5″ pulley

- Shaft to 1.75″ pulley

- Belt to barrel (approx 23″)

- End Result is approx 30 RPM

(This was from memory so might be fractionally off).

Here is a render of the pulley assembly (draft):

Barrel Sander (M002) Wooden Slat

The inside of the barrel tumbler needs a polygon (made from wood) in order to (a) give enough “traction” to turn the contents, and (b) protect the barrel from repeated impacts. I’m going to use Oak or Maple to do this. Based on the width and thickness of available material, I chose a 9-sided polygon.

Here is a picture of the CAM operation prepared using Fusion 360. I will make nine of these with just a fraction of an inch extra that I can remove on the jointer while getting a tight fit.

Perfecting The “Mess”

Golden potatoes, black pepper bacon, onions, green peppers, garlic, salt, pepper, and adobo — topped with cast iron fried eggs. A most excellent breakfast.

Barrel Sander (M002) Intro

Machine M002 is in the works. It is a barrel tumbler for wooden parts. This project will allow us to knock sharp edges off of small wooden products by the hundreds at a time. More to come!

Stain Dipping Machine Cable Winding Pulley

The cable winding pulley was the most complicated part of the machine due to it’s multiple set screws, flat surfaces, precise bore, and threading. One set screw holds the pulley on the shaft. The other set screw holds the cable firmly attached to the pulley.

Here is a picture of the pulley mounted to the DMM Tech Servo Motor. In the background you can see the cable go up through the top of the machine, over the free pulley, and back down to hold the main slider mechanism.