In the Stain Dipper Machine, we have a top pulley which is mounted on a 10mm shaft that is seated in 10x26x8mm bearings. In the last post on this topic, I showed the pulley holder assembly. In this post I’ll show the pulley and the final assembly.

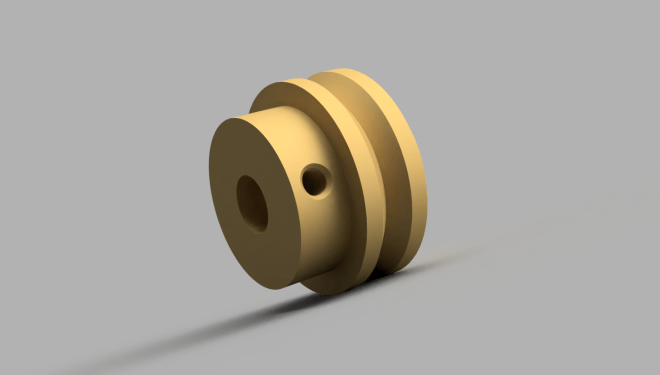

Here is the finished pulley, made from a 1″ long by 1.5″ diameter piece of brass.

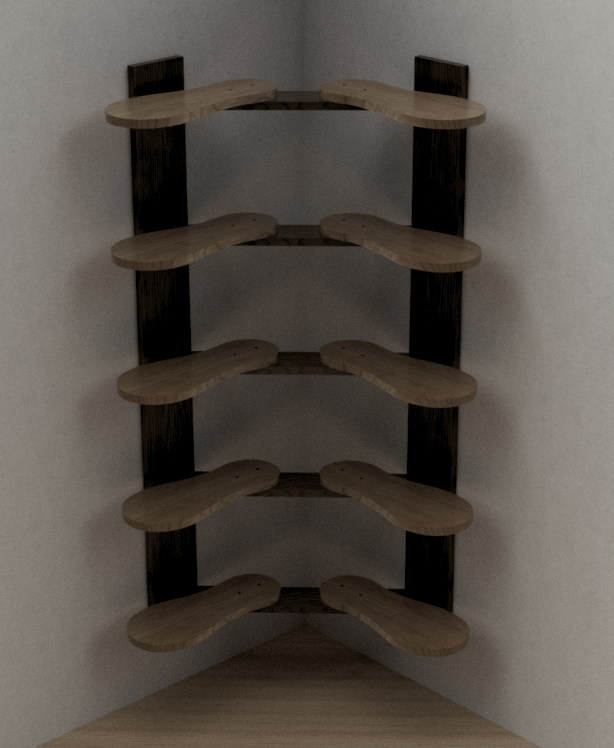

Here is the pulley mounted on the top of the machine. This is a satisfying point in the project because of all the ways this could have been solved, we chose an elegant, smooth, and accurate one. You can’t buy this specific part anywhere in the world – we designed and made it just for this purpose.

Here is a picture of tapping the pulley for a M5 set screw.

This is a picture after the first operation was complete. Now we need to turn it around in the lathe, recenter it, and finish the other side.

Here is a picture of the part in the lathe. Notice the difference in surface finish? The shiny area is freshly cut. The dull area was original surface. The semi-dull area was shiny just an hour before, but oxidization got to it that quickly.

A view of the spinning 4-jaw chuck and quick change tool post.